Latest News & Projects

-

The Benefits Of Pump-Applied Screed

When undertaking substantial construction projects, the method used to apply floor screed can significantly impact efficiency, quality, and project timelines. Pump-applied screed has revolutionised how contractors approach large-scale flooring installations, offering advantages that traditional hand-laying methods cannot match.

Click Here

What Is Pump-Applied Screed?

Pump-applied screed involves using specialist pumping equipment to deliver liquid screed materials directly to the installation area. The screed is mixed off-site or in a dedicated mixer, then pumped through hoses to precisely where it's needed. This method works particularly well with flowing screed materials like anhydrite or self-levelling compounds.

The process differs fundamentally from traditional methods where workers manually mix, transport, and spread screed using wheelbarrows and hand tools. Pump application allows for continuous flow of material, creating a seamless installation process.

Speed & Efficiency

The most st... -

Underfloor Heating & Anhydrite Screed Installation In Ilkeston

Location: Ilkeston, Derbyshire

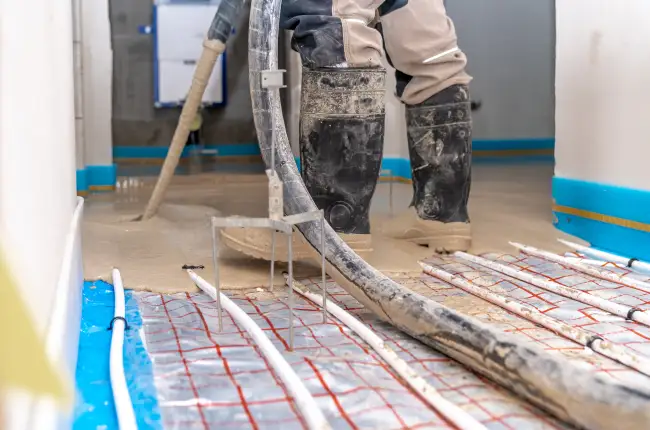

A property owner in Ilkeston required a complete underfloor heating and floor screeding solution for their 157m² property. Mitchell Plastering & Dry Lining Ltd was tasked with installing a full wet underfloor heating system with liquid anhydrite screed, providing an energy-efficient heating solution with a smooth, level floor finish.

Click Here

The project required careful coordination and expert installation to complete all work within a single visit, allowing the customer to return to the property the following day.

The Underfloor Heating Installation Process…

Polythene DPM Installation

The first stage involved laying a polythene damp proof membrane (DPM) across the entire floor area. This membrane provides essential protection against moisture rising through the floor structure, preventing damp problems that could damage the screed and compromise the underfloor heating system.

Polythene DPM comes in sheets that must be laid with overlaps at the joints. Our team positioned the membran... -

Fast Drying Screed: For When Speed Matters…

Meeting Tight Deadlines Without Compromising Quality

Click Here

Construction schedules often leave little room for delays. When flooring needs to be ready quickly for subsequent trades or tight project deadlines loom, standard screed drying times can become a significant bottleneck.

Fast drying screed technology has transformed how builders and contractors approach floor finishing, dramatically reducing waiting periods without sacrificing performance.

At Mitchell Plastering & Dry Lining Ltd, we understand the pressure of keeping projects on schedule.

Our floor screeding contractors provide fast drying screed solutions across the UK, helping commercial and industrial clients meet demanding timelines.

With over 20 years of experience in floor screeding, we know exactly when rapid drying products deliver the best results and how to install them for optimal performance.

Understanding Fast Drying Screeds

Fast drying screeds use specially formulated materials that release moisture much qui... -

Liquid Anhydrite Screed With Underfloor Heating In Derbyshire

Location: Draycott, Derbyshire

At Mitchell Plastering & Dry Lining Ltd, we take pride in delivering comprehensive floor screeding solutions that combine efficiency with exceptional quality.

Click Here

Recently, we completed a flooring project in Draycott for one of our regular builder clients, demonstrating our expertise in liquid anhydrite screed and underfloor heating systems.

Initial Preparation

This particular project involved transforming a 70m2 property with a complete floor screeding system that would provide both thermal efficiency and a perfectly level surface for the final flooring.

Our team began by conducting a site assessment to determine the specific requirements and challenges we would face during the installation process.

The builder had specifically requested our services due to our proven track record in delivering high-quality results within tight timeframes. We understood that the property needed to be ready for occupancy quickly, which meant our screed installation had to be completed efficiently whil... -

Liquid Screed Vs Traditional Sand Cement Screed: Which Is Better?

Choosing The Right Screed For Your Project

Click Here

When undertaking construction projects requiring level floor finishes, selecting appropriate screed material becomes crucial. The choice between liquid screed and traditional sand cement screed significantly impacts project timeline, costs and performance.

Both methods create smooth surfaces ready for floor coverings or underfloor heating. However, their application methods and performance characteristics vary considerably. At Mitchell Plastering & Dry Lining Ltd, our floor screeding contractors have experience with both materials, providing insights into when each performs best.

What Is Traditional Sand Cement Screed?

Traditional sand cement screed combines Portland cement with sharp sand in ratios typically 1:3 to 1:4.5 parts, mixed with water to create workable consistency. Skilled tradespeople spread and level the screed by hand using traditional tools. The material must be tamped and floated to remove air pockets, then finished with s... -

What Thickness Should Floor Screed Be For Underfloor Heating?

Getting The Right Screed Depth For Optimal Heating Performance

Click Here

Determining the correct floor screed thickness for underfloor heating installations is crucial for achieving optimal thermal performance, energy efficiency and long-term reliability. The screed depth directly affects heat distribution, response times and running costs of your underfloor heating solution.

Getting this measurement wrong can result in poor heating performance, increased energy bills and potential structural issues. Whether you're planning a new build or retrofit installation, the correct floor screeding specification forms the foundation of an effective underfloor heating system.

Standard Screed Thickness Requirements

Water-Based Underfloor Heating Solutions

For water-based (wet) underfloor heating arrangements, the recommended screed thickness above the pipes typically ranges from 65mm to 75mm. This depth provides sufficient thermal mass to distribute heat evenly whilst maintaining structural integrity.... -

Liquid Screed Vs Traditional Screed: Which Is Best For Your Project

Understanding The Key Differences Between Modern & Traditional Screeding Methods

Click Here

Choosing the right screed type for your construction project represents a critical decision that affects everything from installation speed to long-term performance. Modern construction has embraced liquid screed technology, but traditional sand and cement screed remains a proven solution for many applications. Understanding the fundamental differences between these two approaches helps you make informed decisions that benefit your project's timeline, budget and performance requirements.

Floor Screeding Contractors regularly encounter clients wondering whether to choose liquid or traditional screed systems. Each method offers distinct advantages depending on project size, timeline constraints, underfloor heating requirements and budget considerations. The choice between these two screeding approaches significantly impacts installation speed, drying times and overall project costs.

Traditional Sand & Cem... -

Concrete Floor Screeding In Mansfield Using BreedonFlow

Location: Mansfield, Nottingham

High-Performance Screed For A Large Site Installation

Click Here

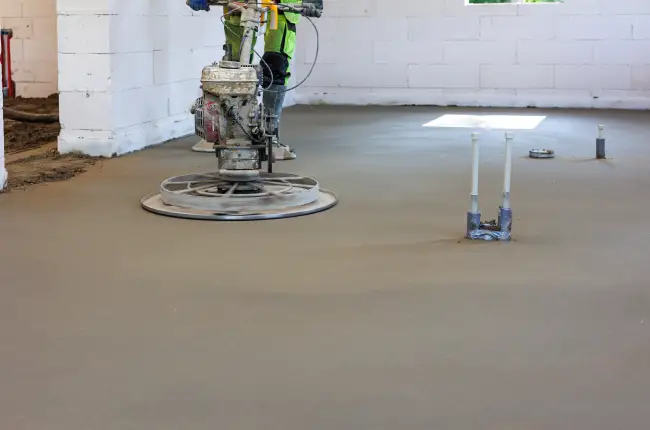

We recently completed a concrete floor screeding job at an active building site in Mansfield. The project involved covering a total of 160m², and we poured 13m³ of BreedonFlow fibre-reinforced material across multiple plots. The job was part of a larger construction schedule, meaning precise planning and efficient execution were essential to keep things moving on site.

BreedonFlow is a self-compacting concrete screed that’s ideal for large surface areas. For this job, we used a version reinforced with steel fibres, which adds extra strength and durability across the entire floor area. The result is a hard-wearing surface that is highly durable and reliable.

Fast, Even Coverage With Self-Compacting Material

BreedonFlow is designed to spread and level itself without the need for excessive tamping or vibration. This makes it particularly useful for covering larger spaces quickly and consistently. On this Mansfield site, it al... -

Floor Priming & Screeding In Ilkeston

Location: Ilkeston, Derbyshire

Preparing Office Factory Unit For Screeding

Click Here

We recently completed a screeding job in Ilkeston for a new office factory unit. The site had underfloor heating installed by another contractor, and we were brought in to complete the floor screed over the top.

The total area was close to 300m2, so it required careful planning to keep the job smooth and safe. We worked in two stages. First, we primed the entire area with a grit primer. Then, the following day, we installed the levelling compound.

Using The Right Materials

This job called for the use of a high-quality levelling compound. We applied 8mm of compound across the full 300m2. It was a large space, and we needed 150 bags of compound to complete the work.

The grit primer helped the compound bond properly to the subfloor. This makes sure the finish stays solid and durable for years. It also helps deal with any minor movement or expansion from the underfloor heating below.

Day One – Grit Primer Application

The first day on sit... -

Home Extension Insulation & Screeding - Insulation and Screeding

Location: West Midlands

Insulation & Screeding For A Garden Room / Office

Click Here

At Mitchell Plastering & Dry Lining Ltd, we specialise in professional floor screeding and insulation solutions for residential and commercial projects. A recent job in the West Midlands involved insulating and screeding a garden room/bar and office, producing a durable and energy-efficient flooring system.

Installing A Reliable Insulation System

To create a solid base for the screed, we started by installing 20mm polystyrene insulation and 75mm Celotex insulation over the client’s 1200-gauge polythene damp-proof membrane (DPM). This combination provides excellent thermal efficiency, helping to keep the space well-insulated throughout the year.

For additional protection and movement accommodation, we fitted a 25mm perimeter upstand along the edges of the flooring. A 6mm expansion strip was also added to allow for natural material expansion and contraction, preventing cracks and achieving long-term performance.

Floor Screeding Wit... -

Floor Repair & Levelling In Ilkeston - Levelling Compound & Liquid Flow Screed

Location: Ilkeston, Derbyshire

Preparing A Floor For A Full House Renovation In Hallam, Ilkeston

Click Here

At Mitchell Plastering & Dry Lining Ltd, we recently completed a full floor repair and levelling project in Hallam, Ilkeston, as part of a complete house renovation led by a local builder. Our role was to prepare the floors for final finishes, achieving a smooth, level, and durable surface suitable for any chosen flooring material.

This project required working with a variety of existing substrates including concrete, ceramic tiles and sand-cement screed. To achieve the best results, we used specialist floor levelling products to create a seamless and long-lasting surface.

Floor Preparation & Crack Repairs

Before any levelling work could begin, our team sanded and vacuumed the existing floor to remove any dust, dirt or surface irregularities. Once the floor was fully prepped, we carried out the following works:

Filled all cracks and holes using professional crack repair materials to prevent future movement.

Appli... -

Commercial Offices - Fast Drying Screed

Location: Brassington, Matlock

Contract Duration: 1 Day

Working for a local client to convert this building into a commercial office.

Click Here

We installed a taped & lapped 1200 gauge membrane, 5mm perimeter isolation strip with fast drying screed supplied by Rightmix to cover 205m2. -

Enrok Construction - New Medical Centre

Location: Nuneaton

Contract Duration: 2 weeks

Our final update on Hartshill Medical Centre in Nuneaton for Enrok construction, we have now completed the installation of insulation, underfloor heating and liquid flow screed to both the ground floor and 1st floor.

Click Here

The ground floor consisted of 36m3 of Tarmac’s liquid flow screed (screed A) laid on 500gg polythene separating membrane on 120mm Celotex & 25mm EPS70 polystyrene along with a 25mm Celotex upstand to all exterior walls and a 5mm foam expansion strip to all walls.

On the first floor 32m3 of Tarmac’s liquid flow screed (screed A) laid on 500gg polythene separating membrane on 50mm Celotex & 15mm EPS70 polystyrene with a 5mm foam expansion strip to all walls.

Part of package included the installation of the underfloor heating which consisted of 6 manifolds (2 on the 1st floor and 4 on the ground floor). 16mm pipes, tracker clips, 42 thermostats and 52 thermal actuators.

The new medical centre will be a huge asset to the local community once it’s completed, we are pl... -

Private Development - Underfloor Heating & Liquid Flow Screed

Location: Risley - Derbyshire

Contract Duration: 2 days

Another local project in which the team at Stuart Mitchell's supplied a complete flooring solution with all preparation work, underfloor heating and liquid flow screed.

Click Here

The first day we prepared the house with 100mm insulation and membrane before installing the 8 port manifold and pipework.

The next day we returned to site and completed the work by laying 5.2m3 of Breedon Gypscreed. -

3 New Build Bungalows - Underfloor Heating & Liquid Flow Screed

Location: Ripley

Contract Duration: 1 week

A new client requested us to install underfloor heating and screed for three new bungalows.

Click Here

The under floor heating systems that are fixed to manifold comprise of 7 Port (Type A) of 6 Port (Type B) Manifold with inserts and pipe bends, 2 x Thermomix – pump and mixing set to suit boiler, 2 x Master Wiring Centre, 13 x Thermal Actuators for individual control, 13 x Digital Room Thermostats, 2 x Probes and 16mm Pipe, Staples & Conduit.

A 50mm liquid flow screed was supplied and the insulation comprised of 150mm celotex, 25mm EPS70 polystyrene with damp proof membranes, upstands and expansion strips to all walls -

House Refurbishment - Levelling Compound

Location: Loughborough

Contract Duration: 3 hours

Another small floor refurbishment for an existing client in Loughborough. The client required the kitchen & hall floor to be level to receive new floor coverings at a future date.

Click Here

To achieve this we had to sand and vacuum the floor, prime it and finally applied 18 bags of Mapei renovation to create an even surface for the floor coverings.